- This is a verified supplier can provide quality products and have passed the Business License Check.

Home>Products>fried wheat flour snack processing machine>China FRIED WHEAT FLOUR SNACKS PROCESS LINE

China FRIED WHEAT FLOUR SNACKS PROCESS LINE

- LD

LDM

- Original China FRIED WHEAT FLOUR SNACKS PROCESS LINE

- CE, ISO9001

- Negotiation

- Negotiable

- Original package

- Within 5 working days

- paypal,UnionPay, Visa/MasterCard, Amex, Discover,T/T

- 78

-

2020-07-10 09:46:19

Welcome to my shop! Glad to serve you! Please send your question!

2020-07-10 09:46:19

Welcome to my shop! Glad to serve you! Please send your question!

Product Description

| Place of Origin : | China |

|---|---|

| Brand Name : | LD |

| Certification : | CE, ISO9001 |

| Model Number : | LDM |

| MOQ : | 1 set |

| Price : | Negotiation |

| Packaging Details : | In wooden case or nude pack after wraping by plastic film |

| Delivery Time : | 40-60 days after receiving the downpayment |

| Payment Terms : | L/C,T/T |

| Supply Ability : | 30 sets per quarter |

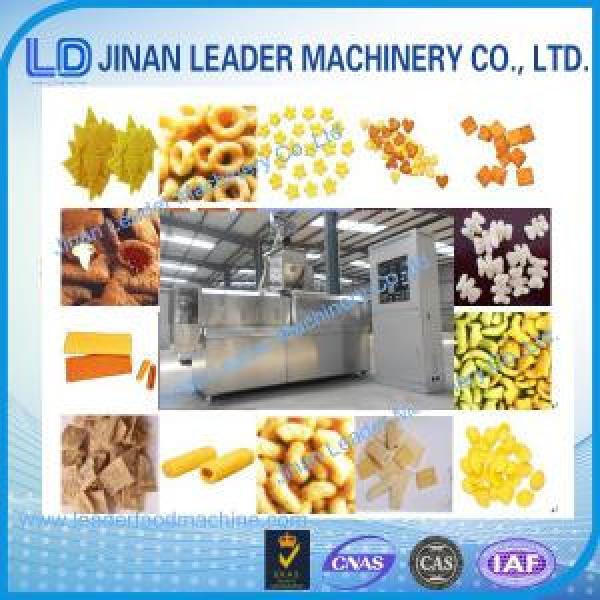

FRIED WHEAT FLOUR PILLOW/STICK SNACKS PROCESS LINE

1. DESCRIPTION OF FRIED WHEAT FLOUR PILLOW/STICK SNACK PROCESS LINE

Fried Wheat Flour Pillow/Stick Snack Process Line uses wheat flour as main materials and is shaped by the compound roller pressing machine. After frying and flavoring by fryer machine and drum flavoring machine, we can get crispy and delicious snacks food. It has features of continuous working, stable performance, compact design structure.

2.RAW MATERIALS: Wheat Flour

3.PRODUCTS: Fried Wheat Flour Pillow/Stick Snack

4.CAPACITY: 100KG/H

5.VOLTAGE: Three phases: 380V/50HZ, Single phase: 220V/50HZ, we can make it according to customers' local voltage according to different countries.

6.MACHINES MATERIALS: All the machines are made by food grade stainless steel

7. PACKAGING DETAILS: Your machines are always wrapped by film completely and safely and then packed in strong fumigation-free case or 20'/40' container for delivery. We take good care of each machine for you!

8. DELIVERY DETAIL: 45-60Days after Receiving the Down Payment

9.TECHNICAL PARAMETERS

Model | Installed Power | Power Consumption | Output | Size(L×W× H) |

LDM-D Electric Heating | 60kw | 50kw | 250-300kg/h | 23000x1500x1800mm |

LDM-G Diesel Heating | 12L/H(Diesel) | 8-12L/H(Diesel) | 250-300kg/h | 23000x1600x1800mm |

10. FLOW CHART

Mixing—Extrusion—Separating—Frying— Flavoring

11. WHY YOU MUST CHOOSE US

a.) Double-layer 304 stainless steel mesh belt, pressing material between them, preventing from floating, and frying it fully.

b.)There are scrapers on the upper belt, automatically taking material forwards to the other side.

c.) When cleaning the parts inside fryer, belt and housing can be lifted automatically by pressing the button on the support.

d.) Material of controller casing can be stainless steel or plastic coating.

e.) Automatic oil lever alarm, timely reminding workers to add oil. With our matched system, it can be realized automatically.

Time, speed and temperature of frying can be adjusted and controlled as per your requirement.

12. WE PROVIDE SATISFIED SERVICE & TURNKEY SOLUTION

a.) Consultation service before, during, and after sales;

b.) Project planning and design service;

c.) Debugging of equipment until everything is functional;

d.) Management of equipments' long distance shipping from seller's factory to the named place by buyer;

e.) Training of equipment maintenance and operating personally;

d.) New production techniques and formulas;

e.) Provide 1 year complete warranty and life-time maintenance service.

13.Product Image

Global Market

Contact Us

Contact Us

- Phone(Working Time)

Product Categories

- puffed snack food processing machine

- core filling snack processing machine

- pet fish animal food processing machine

- breakfast cereal corn flake processing machine

- macaroni pasta processing machine

- fried wheat flour snack processing machine

- potato chips making machine

- kurkure snack production line

- cookie biscuit production line

- doritos production line

- artificial nutrition rice processing line

- nutrition powder processing line

- drying oven belt dryer

- frying machine fryer

- double twin screw extruder

- singe screw extruder

- accessory equipment for food machinery

- bread crumb production line

- crispy chips salad bugles process line

- fruit and vegetable chips process line

- instant noodles process line

- modified pregelatized starch process machine

- nutrition bar processing machine

- nutrition rice artificial rice process line

- oven dryer roaster machinery

- popcorn process machine

- screw shell extruded pellet frying food process line

- tvp tsp soya bean protein food machine

- vertical pillow packing machine

Chinese FRIED WHEAT FLOUR SNACKS MAKING MACHINE

Chinese FRIED WHEAT FLOUR SNACKS MAKING MACHINE China Manufacturer FRIED WHEAT FLOUR CHIPS MAKING MACHINE

China Manufacturer FRIED WHEAT FLOUR CHIPS MAKING MACHINE Big Capacity FRIED WHEAT FLOUR CHIPS MAKING MACHINERY

Big Capacity FRIED WHEAT FLOUR CHIPS MAKING MACHINERY FRIED WHEAT FLOUR PILLOW/STICK SNACKS PROCESS LINE

FRIED WHEAT FLOUR PILLOW/STICK SNACKS PROCESS LINE